Particle Size Distribution

Method Overview

- Most collection devices are sized using Stokes particle size distribution data. A good deal of this work was generated years ago using data from a Bahco™ Centrifugal Classifier. The Bahco is the particle sizing device recommended by the Industrial Gas Cleaning Institute to determine particle size and collection efficiency of mechanical collectors. It was also the device used to gather data for the Electric Power Research Institute’s Electrostatic Precipitator Model (ESP Computer Model). Operation and calibration of the Bahco™ is described in the American Society of Mechanical Engineers Power Test Code 28[1].

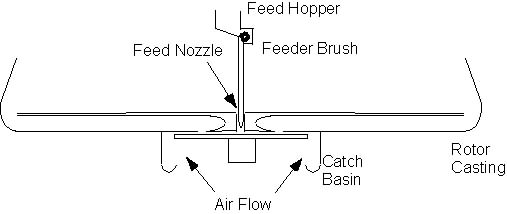

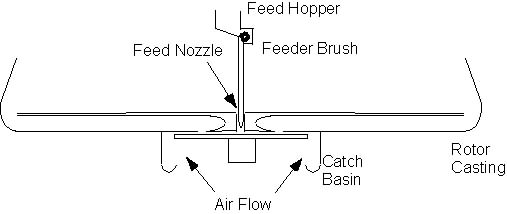

- The Bahco™ Centrifugal Classifier is a combination air centrifuge-elutriator consisting of a rotor assembly driven by a totally enclosed electrical motor. The sample is introduced into a spiral shaped air current flowing toward the center. The spiral current of air has suitable values of tangential and radial velocities so that a certain part of the sample is accelerated by the centrifugal force toward the periphery of the whirl, the other part of the sample is being carried by the air current toward the center of the whirl by aerodynamic means. The size, shape and mass of the particles individually determines which direction they will take in the air current.

- By varying the air flow, it is possible to change the terminal velocity limit of division and thus the material can be divided into a number of fractions with limited terminal velocity ranges. The instrument has eight calibrated throat spacing rings for eight different air flows. These throat spacing rings are set for flow rates that nominally separate particles into eight size ranges between one and twenty-five micrometers.

- Technique Advantages

- This technique is well-adapted for bulk materials and is non-destructive.

- Each cut-point can be recovered for future size-respective chemical analysis and/or characterization.

- Particle size is determined as a function of settling velocity in an air stream (as opposed to some other fluid).

- Particle density measurements will allow determination of Stokes diameters.

- Technique Disadvantages

- A bulk sample (about 8-10 grams) must be obtained.

- The technique is a fairly time-consuming manual feed method.

- The actual ASME test method has been withdrawn due to obsolescence. Instrument calibration materials are therefore generally not available.

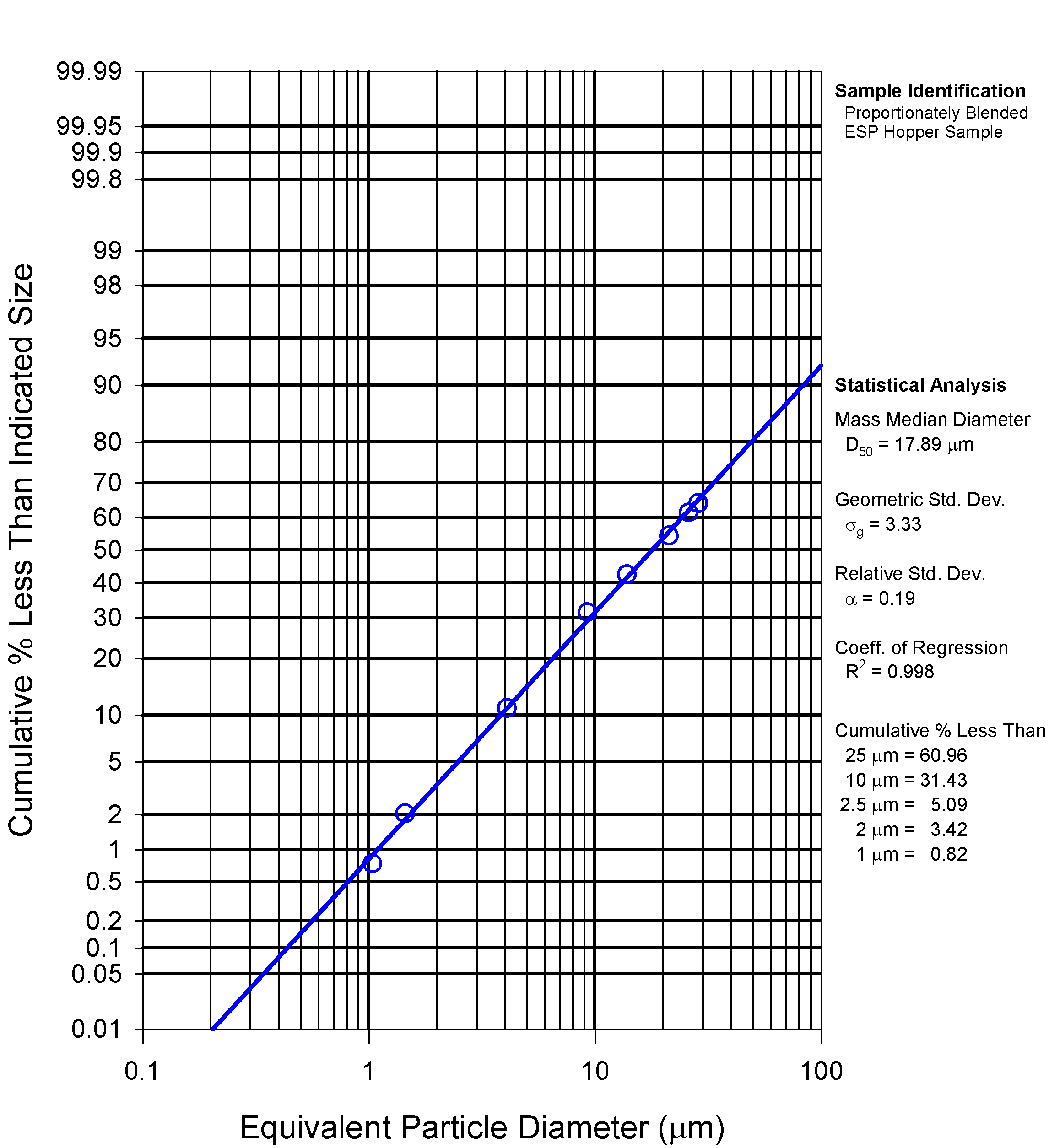

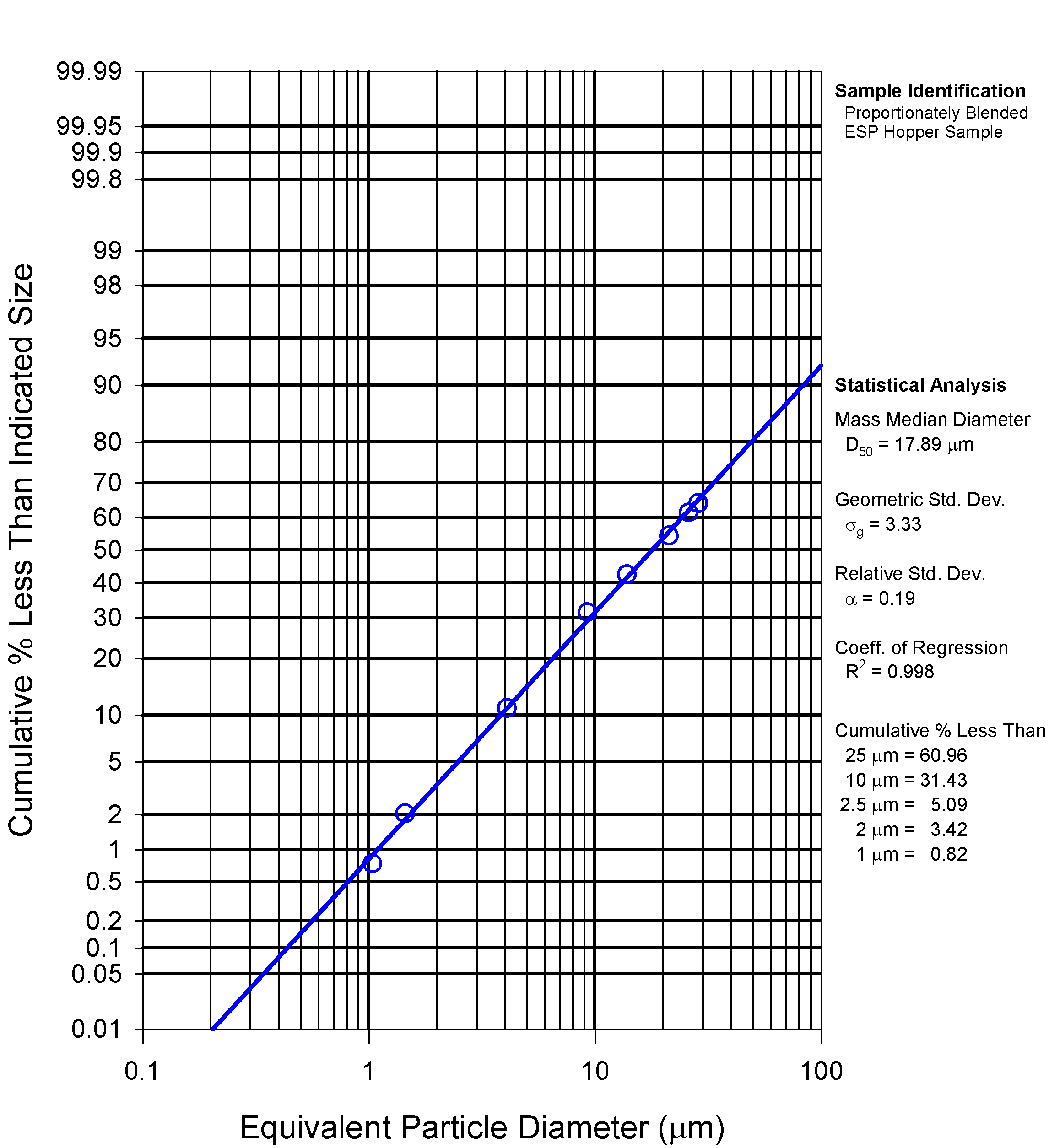

- An example size distribution is shown in Figure 1, below.

- The image below shows particle size distribution in accordance with ASME Power Test Code 28 using a BachoTM Centrifugal Classifier.

Target Compounds

- Not really a compound-specific analysis. This algorithm determines the electrical properties of a dust. These properties can be used to determine the effectiveness of:

- Coal-switching studies that evaluate the resistivity of select coals and blends to predict precipitator collection performance;

- Flue gas conditioning used to improve precipitator collection performance; and

- Precipitator design and optimization studies.

Performance Tips

- A bulk sample (about ten grams) is required for this analysis. Optimally, samples should be pulled from every precipitator hopper and blended into a representative inlet sample. This is simple across the rows, a little more involved from inlet to outlet. The Deutsch-Anderson equation is used along with hopper mapping to blend samples in a row from inlet to outlet fields.

- Isokinetic samples can also be used for this analysis. One major inconvenience is the bulk quantity required for the measurements.

Shipping

- Flyash samples are generally non-hazardous for shipping purposes.

- Samples should be shipped in airtight containers.

Applications

- Modeled resistivity is well-suited for predictions of how well a candidate coal will work. It can also predict:

- How well sulfuric acid conditioning might help a given situation;

- How well temperature changes might affect a given situation;

- The resistivity of fuel blends.

Accreditation

- No, please contact us if you are interested!